Option 1

Doing inspection in Joyeux warehouse, free storage for 1-2 months.

option 2

Doing inspection in third-party warehouse or in the factory.

When you choose our Pro Plan and use our selected suppliers, we will guarantee the quality of your products.

Share your wedding moments with your guests

How we inspect your products in our warehouse or factory

General inspection

Regardless of whether you’re on the Pro or Basic plan, your goods will undergo a free general inspection at our warehouse. We adhere to Level II, AQL 2.5 standards, just like other inspection agencies.

If you’re using our preferred suppliers, we will address any quality issues at no extra charge. If you’re sourcing from your own suppliers, we can help resolve the problems, but please note that logistics and travel fees may apply.

For tailored inspection solutions or to achieve a lower defect rate, please reach out to our agent for more details on any extra charges.

Audit Service We offer

Rely on Our Team of Professionals

Our inspectors are highly skilled and specialized, allowing clients to benefit from their product knowledge. Based on the audit criteria, we will propose a tailored audit plan based on a risk evaluation and collaborate with clients to determine the next steps. This includes varying Acceptable Quality Levels (AQL) based on statistical sampling methods, as well as adjusting the timing of the audit.

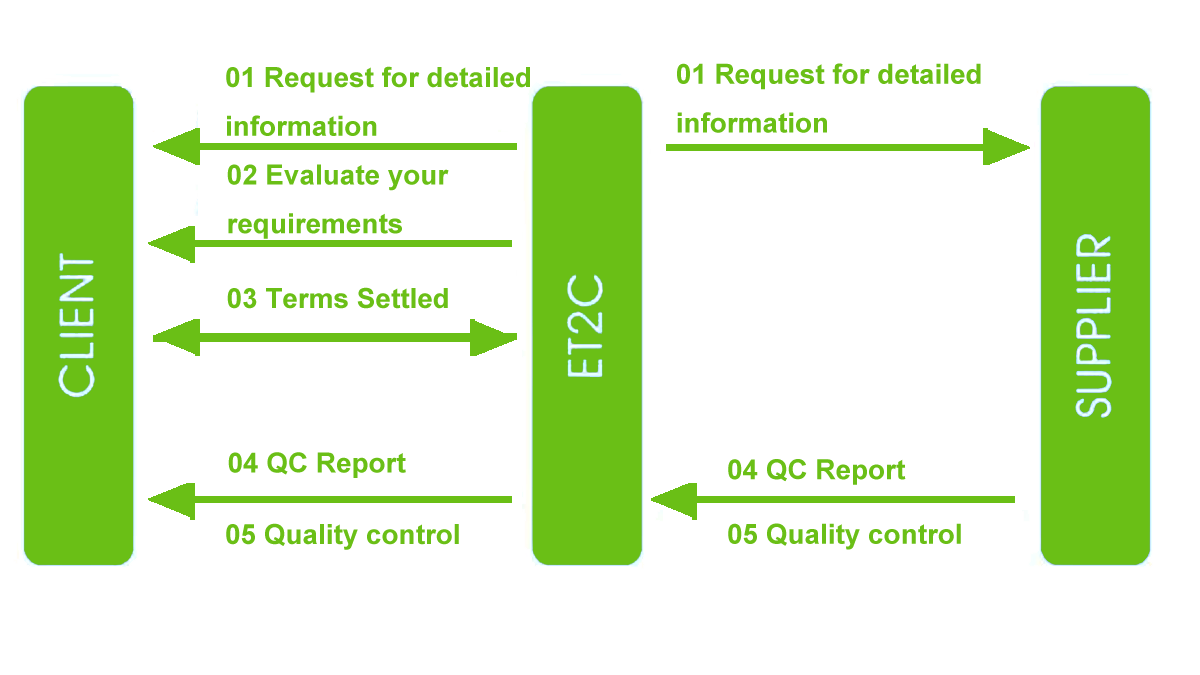

Third Party QC Process